The DIY wiring clue that tells inspectors to look closer everywhere else

Home inspectors will tell you that the most revealing part of an electrical system is often the first outlet or switch they open. One sloppy DIY fix in that box is rarely an isolated mistake, it is a clue that the rest of the house may be wired with the same casual shortcuts. If you understand why that one detail sets off alarms, you can spot trouble earlier, protect your budget, and keep your home safer.

The core idea is simple: amateur wiring is not just untidy, it is a pattern. Once an inspector sees mismatched wires, loose terminations, or improvised grounding in one location, they start looking harder at every other system in the house. When you recognize the same warning signs, you can decide when to walk away from a property, when to renegotiate, and when to call a licensed electrician before a small issue becomes a serious hazard.

The first DIY clue inspectors look for

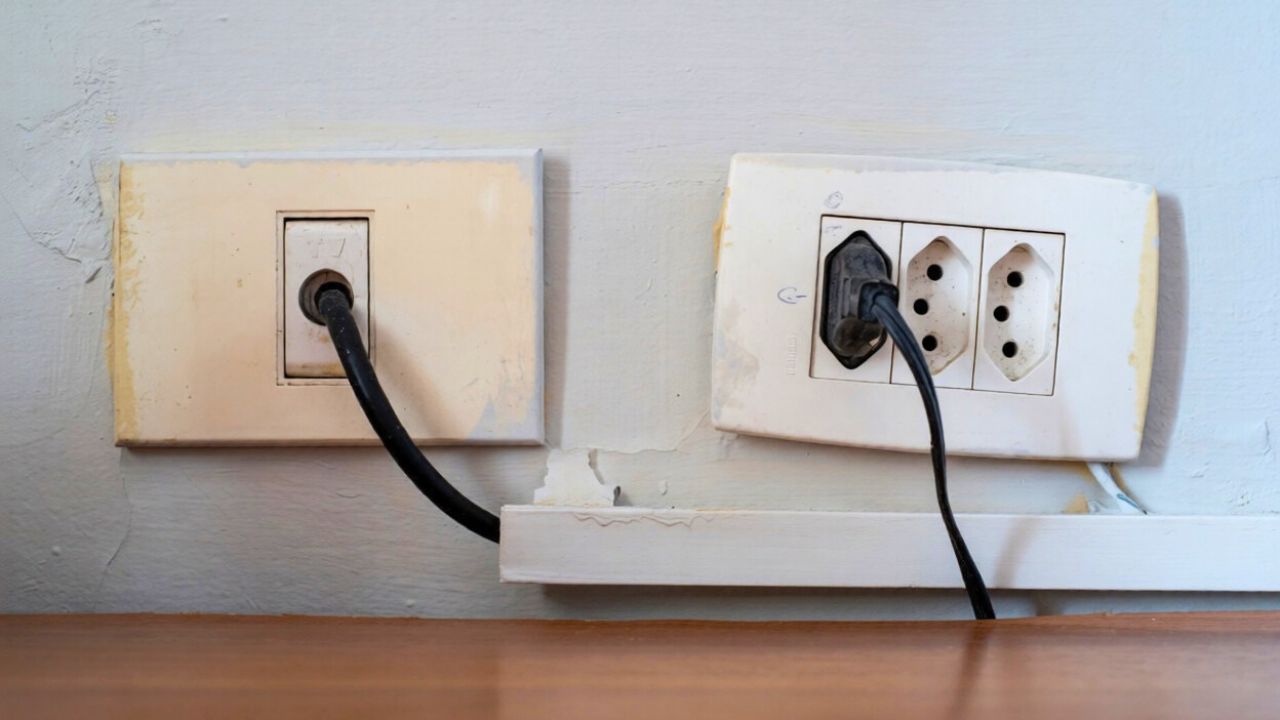

When a home inspector walks into a house, they are already scanning for hints that someone has been experimenting with the electrical system. Long before anyone opens a panel, details like mismatched cover plates, crooked outlets, or paint-splattered switches suggest that a previous owner treated wiring as another weekend project. Inspectors know that one of the most common DIY red flags is electrical work that was never permitted or inspected, so they treat any obvious tinkering as a sign that more problems may be hiding behind the walls. That is why a single amateur junction box or oddly placed outlet can instantly change the tone of an inspection from routine to investigative.

Once they see that kind of improvised work, inspectors start connecting it to broader safety concerns. Reporting on DIY electrical fixes notes that Jan and other professionals often find that what a seller calls a “simple upgrade” is actually a tangle of unapproved splices and overloaded circuits. One of the key lessons from that kind of field experience is that a single bad outlet is rarely alone. Once the first clue appears, the red flags multiply quickly, and inspectors start widening their search to attics, crawl spaces, and exterior receptacles that might otherwise get only a quick glance.

Why incorrect outlets trigger a deeper inspection

Among all the possible clues, incorrect outlet and switch wiring is the one that most reliably tells inspectors to slow down and dig deeper. When you reverse hot and neutral, skip a ground, or double up wires on a single terminal, you are not just bending a rule, you are creating a condition that can shock someone or start a fire. Inspectors know that if a homeowner did not understand the basics at the outlet level, they almost certainly did not size breakers correctly, respect box fill limits, or follow code for junctions elsewhere in the system. That is why a single miswired receptacle can turn a quick walkthrough into a methodical room by room review.

Guidance on incorrect outlet and explains that faulty work at this level is one of the leading reasons electrical systems fail inspection. The same pattern shows up in checklists that highlight “Incorrect Outlet and Switch Wiring” and describe how such faulty terminations can cause arcing, nuisance tripping, or silent overheating. For you as a buyer or homeowner, that means a cheap plug tester that reveals reversed polarity or an open ground is not just a minor annoyance, it is a prompt to ask what else was done to the same standard in the rest of the house.

How one bad fix hints at a pattern behind the walls

Inspectors think in patterns, not isolated defects. When they find a single junction box crammed with too many conductors or a light fixture fed by a random extension cord, they do not assume it is a one off mistake. They assume it reflects the skill level and habits of whoever last touched the system. If that person was comfortable burying an open splice in insulation or mixing aluminum and copper without proper connectors, the odds are high that similar shortcuts exist in other rooms, in the panel, and even at the service entrance. One clue, in other words, becomes a working theory about the entire installation.

That pattern based thinking is reinforced by lists of the most common electric inspectors encounter, which often include overloaded boxes, missing clamps, and the use of extension cords as permanent wiring. Engineering focused breakdowns of Common Electrical Issues in Home Inspections emphasize “Unsafe Wire Connections” and “Terminations” as repeat offenders, especially when two wires connect without proper devices or when receptacles are daisy chained in ways that violate code. When you see one of these issues in a visible location, you should assume it is the tip of a larger pattern and budget for a licensed electrician to open more walls than you might like.

What actually fails an electrical inspection

From a homeowner’s perspective, it helps to know exactly what will cause an inspector to fail an electrical system. Loose, ungrounded, or incorrectly wired devices are at the top of that list, because they directly affect safety every time someone plugs in a lamp or flips a switch. Inspectors also look for missing or damaged cover plates, exposed live parts, and any sign that conductors are undersized for the breaker protecting them. Each of these issues suggests that the system was not installed or maintained by someone who understands the National Electrical Code, which is why they are treated as more than cosmetic flaws.

Guides that explain Understanding the most common reasons for failure highlight how these basic errors undermine the reliability of the entire system. They stress that being proactive, rather than waiting for an official inspection, is the best way to keep your home safe. When you combine that with engineering notes on Improperly Wired Receptacles and other defects that must be corrected by a licensed electrician, the message is clear. If you see the same kinds of issues that would fail an inspection, you should treat them as urgent, even if no official is currently writing up a report.

Real world DIY disasters inspectors keep seeing

The abstract idea of “bad DIY wiring” becomes much clearer when you look at real examples. In one widely shared case, a Customer stated that outlets in the living room randomly stopped working. When an electrician opened the box, they found 2 wire BX cable with the jacket grounded in a way that suggested a previous owner and their handyman had improvised a fix instead of running a proper equipment grounding conductor. That one discovery did not just explain the intermittent power, it also told the inspector that the same duo had probably “repaired” other parts of the house with similar creativity.

Online communities for professionals and serious hobbyists are full of similar cautionary tales. One homeowner seeking feedback on a DIY EVSE install described how the easiest place to ground the EVSE was the grounding bar that was installed when a sub panel was added. Only the sub panel was properly bonded at the time, and the main panel was not, which meant the new charging equipment was relying on a grounding path that no longer met code. Another thread cataloging the “12 Most Common DIY Electrical Mistakes” notes how a Previous owner often uses the wrong gauge wire or tries to extend circuits with whatever scrap is on hand. For inspectors, these stories are not entertainment, they are a reminder that the same patterns show up again and again in real houses.

The most common DIY wiring mistakes hiding in plain sight

If you want to think like an inspector, you need to know which mistakes show up most often. Using the wrong wire size is near the top of that list, because it quietly turns a normal load into a potential overheating hazard. When a homeowner runs 14 gauge wire on a 20 amp breaker to save a few dollars or reuse leftovers, the conductor can overheat long before the breaker trips. Improper wire connections are another frequent problem, especially when people twist wires together without proper connectors or rely on backstabbed receptacle terminals that loosen over time.

Guides that spell out Here are some common DIY wiring mistakes list “Using the Wrong Wire Size,” “Improper Wire Connections,” and “Overloading Circuit” as core issues that show up in many amateur projects. The same themes appear in discussions of the Use of the wrong gauge wire, often by a previous owner or current owner trying to wire an extra outlet without understanding the load. When you walk through a house and see multiple add on outlets, power strips feeding permanent appliances, or extension cords snaked through doorways, you are looking at the visible side of the same underlying habits that inspectors flag behind the scenes.

Why amateur work in one area hints at trouble in others

Electrical work rarely exists in isolation. The same person who is comfortable burying a junction box behind drywall is often the one who installed a deck without proper flashing or added a bathroom fan that vents into the attic instead of outside. Inspectors are trained to treat “signs of amateur work” as a global indicator, not a narrow one. If they see uneven surfaces, visible seams, or walls that bow slightly, they start to wonder what kind of plumbing or wiring decisions are hiding behind those finishes. One bad patch job can therefore trigger a much more skeptical look at the entire property.

Homebuyer checklists that highlight Signs of amateur work explain that these cosmetic issues may point to structural or electrical problems hidden behind the walls. Risk management guidance for inspectors notes that Here is the challenge. If you identify one code violation, your clients may expect you to point out every violation, even for future projects. That expectation pushes inspectors to be even more cautious when they see DIY fingerprints in any system. For you, the takeaway is straightforward. If one part of the house looks improvised, assume the rest deserves a closer look too.

How inspectors build a routine to catch hidden hazards

Behind every sharp eyed inspection is a routine that has been refined through trial and error. Inspectors do not rely on intuition alone, they follow a consistent sequence that helps them notice small clues before they blend into the background. They might start at the exterior service, move to the main panel, then sample outlets and switches in each room, all while watching for patterns that suggest DIY involvement. When they find a problem, they circle back to related systems instead of assuming the issue is isolated.

Professional associations emphasize that Fitting home inspector duties into a solid routine often happens through trial and error, as each inspector learns which shortcuts lead to missed defects. That same mindset can help you as a homeowner or buyer. If you always test a sample of outlets, look inside at least one accessible junction box, and compare visible work to what you see in the panel, you are more likely to catch the DIY clue that tells you to keep digging. Over time, that habit becomes your own version of a professional routine, one that makes it harder for dangerous wiring to hide in plain sight.

What weekend projects miss about real electrical risk

Many DIY wiring projects start with good intentions. You want a brighter room, a cleaner basement, or a new outlet for a growing stack of chargers. The problem is that weekend projects often focus on the visible result, not the invisible risk. It is easy to assume that if a light turns on or an outlet works, the job is done. Inspectors, by contrast, are trained to ask whether the circuit is overloaded, whether the connections are secure, and whether the installation will still be safe years from now when insulation settles and loads change.

Like Fix It Homestead’s content? Be sure to follow us.

Here’s more from us:

- I made Joanna Gaines’s Friendsgiving casserole and here is what I would keep

- Pump Shotguns That Jam the Moment You Actually Need Them

- The First 5 Things Guests Notice About Your Living Room at Christmas

- What Caliber Works Best for Groundhogs, Armadillos, and Other Digging Pests?

- Rifles worth keeping by the back door on any rural property

*This article was developed with AI-powered tools and has been carefully reviewed by our editors.