The best way to document a job site before problems start

On a well run project, the most valuable paperwork is often the documentation you hope you never have to use. When you capture job site conditions methodically before anything goes wrong, you turn potential arguments into straightforward facts and protect your schedule, margins, and reputation. The best approach is not a stack of photos taken in a panic after a delay, but a disciplined system that starts on day one and quietly runs in the background of every shift.

That system blends clear processes, the right tools, and habits your crews can actually sustain in the field. If you design it carefully, your records will stand up in a dispute, support safety and quality, and give you real time visibility into what is happening on site long before problems surface.

Why “before problems start” is your real leverage point

You gain the most leverage from documentation when you treat it as part of project setup, not as a reaction to conflict. Once a schedule slip, safety incident, or payment dispute is already in motion, everyone’s memory is colored by stress and self protection. If you have neutral records from the first mobilization, you can show what was promised, what was delivered, and how conditions changed, without relying on anyone’s recollection.

Construction experts stress that properly documenting job site conditions is often the single most effective way to avoid costly disputes, because contemporaneous records become the most powerful and objective evidence when you need to prove what actually happened. Guidance on how to compile all records emphasizes that you should be able to reconstruct the story of a project from your files alone, without filling gaps later with guesswork or conflicting testimony.

Start with a baseline: capturing conditions before work begins

The most overlooked step in job site documentation is the pre work baseline. Before equipment rolls in or demolition starts, you should walk the site with a structured checklist, capturing existing damage, access constraints, nearby properties, and any utilities or environmental factors that could later be blamed on your work. This baseline is your reference point when someone claims a crack, leak, or obstruction appeared during construction.

Best practice is to conduct this walkthrough before work starts, record who is on site, and log hours worked from day one, so you can show exactly when your responsibility began and what you found. Detailed guidance on how to document job site conditions recommends treating this as a formal step in mobilization, not an informal photo dump, so that your baseline is consistent across projects and can be compared directly to later inspections.

Designing a pre job briefing that doubles as documentation

Strong documentation starts with how you brief your crews. A pre job meeting is not only about safety and logistics, it is also your first opportunity to lock in what “good” looks like for that specific site. When you capture scope, hazards, controls, and responsibilities in writing, then have the team acknowledge it, you create a shared reference that can be used later to show what was communicated and agreed.

A structured job briefing, sometimes called a pre job briefing, helps teams understand expectations and regulatory requirements in a way that is both operational and auditable. Guidance on how to create an effective and compliant job briefing form highlights that the form itself should capture hazards, procedures, PPE, and special conditions, so it becomes a living record of how you planned to manage risk on that site, not just a meeting agenda that disappears after the toolbox talk.

Make visuals your default language on site

On a busy job, photos and video often communicate more clearly than text. Instead of relying on long narrative notes, you can standardize visual capture so that every area, trade, and milestone is documented in a consistent way. This is especially powerful when you need to show progress, verify that work was in place before it was covered, or demonstrate that a condition existed before an incident.

Modern guidance on what “good documentation” looks like in construction argues that good documentation is visual, and that 360 imagery is increasingly the default for capturing complex spaces, speeding up remote reviews, and enabling fast decision making. When you treat Good Documentation Is Visual and use 360 capture as a standard, you reduce ambiguity about what was in place at a given time and make it easier for project managers, owners, and inspectors to understand conditions without being physically present.

Choosing a documentation app that actually fits the field

Even the best process will fail if your crews have to fight their tools. A dedicated construction site documentation app can replace paper logs, scattered text messages, and ad hoc photo albums with a single workflow that captures data, images, and signatures in context. The key is to choose a platform that matches how your teams already work, instead of forcing them into a rigid system that slows them down.

Specialized platforms are designed to act as a professional documentation app, with features like time stamped photos, standardized forms, and GPS verification for every upload so you can prove where and when records were created. When you evaluate what a Construction Site Documentation App should provide, look for offline capability, simple templates for daily reports and inspections, and an interface that foremen can use quickly between tasks rather than at the end of a long shift.

Structure and version control: treating site records like project data

Once you are capturing information reliably, the next challenge is keeping it organized. Unstructured folders and email chains make it hard to find the right record when a question arises, and they increase the risk that people are working from outdated drawings or instructions. You need a clear taxonomy for your files and a single source of truth for each document type, from RFIs to inspection reports.

Technology leaders in construction emphasize that clean, consistent, well structured data is becoming a core project asset, not an afterthought, and that digital platforms should be configured so information is easy to search and reuse. Recommendations on how Construction teams manage information highlight the value of standard naming conventions and metadata. Complementing that, document management guidance stresses the need to implement version control and use tools that automatically track document versions and allow you to revert to previous versions, so everyone is working from the most up to date information and errors are reduced. When you Implement Version Control in your job site documentation, you can show exactly which plan or procedure was in effect at the time of any decision.

Safety inspections and digital forms as early warning systems

Safety documentation is often treated as a compliance checkbox, but it can be one of your best early warning systems for emerging problems. When supervisors complete inspections in real time and log near misses, equipment issues, and housekeeping concerns, you get a live picture of risk on the site. That record can show whether an incident was a bolt from the blue or the predictable result of trends you had already flagged.

Digital inspection forms make this practical by standardizing questions, capturing photos, and routing issues for follow up without waiting for paperwork to be turned in. Guidance on how to Start 2026 with a Stronger Safety Foundation notes that safer job sites do not happen by chance, and that consistent digital inspections are the place to start. When you embed these forms into your daily routine, you create a continuous record of conditions that can demonstrate diligence if regulators or insurers later scrutinize your site.

Protecting the integrity and security of your records

Documentation only helps you if it is trustworthy and available when you need it. That means protecting your systems from outages, accidental deletion, and cyber attacks that could compromise or alter records. Construction firms increasingly depend on cloud platforms, mobile apps, and shared drives, so you need to treat IT readiness as part of your risk management, not a separate back office concern.

IT specialists warn that many attacks succeed because basic protections are missing, and they urge construction leaders to follow a 2026 IT readiness checklist that includes strong passwords, multi factor authentication, and careful control of admin level permissions. When you follow a Readiness Checklist tailored to construction, you reduce the risk that critical job site records are lost, corrupted, or accessed by unauthorized parties, which in turn strengthens your position if your documentation is ever examined in an audit or legal proceeding.

From job site logs to people, payroll, and investigations

The discipline you apply on site should extend to the way you document people related processes that intersect with field work. Clear payroll procedures, for example, help you show that hours, classifications, and pay rates match what was agreed, which can be crucial in wage disputes or audits. Your process documentation should be detailed, supported by examples and visuals, and reviewed by multiple team members to close any information gaps and ensure accuracy, so that your records of time and pay align with your site logs and daily reports.

HR and legal guidance on workplace records stresses that you should be specific and factual, focusing on observable behavior and outcomes rather than opinions, so that documentation can support fair decisions and highlight areas for improvement and clarification. When you follow advice on Your process documentation and on why Why Workplace Documentation Matters, you create a consistent standard that applies whether you are recording a safety coaching conversation, a performance issue, or a commendation for exceptional work on site.

Signatures, work orders, and centralized investigation files

Sign offs are often the final link that turns a record into binding evidence. When you can show that a client, inspector, or crew member reviewed and signed a document at a specific time, it becomes much harder to dispute later. Digital workflows make this easier by embedding signatures directly into work orders, inspections, and incident reports, so you are not chasing paper or trying to match loose pages to specific events.

Service management tools now offer work order creation and signing software so that some jobs can capture digital proof, instant updates, and real signatures in one place, allowing you to generate work orders, attach photos, and collect e signatures in a single system. Guidance on Work order creation highlights how this supports both operations and documentation. On the safety side, digital signature boxes can be used to quickly collect incident relevant signatures and sign offs, and finally, completed incident forms can be automatically routed to safety, HR, and other relevant departments for immediate action, as guidance on Digital Signature workflows explains. To keep these records usable, you should ensure that nothing related to an investigation is scattered across personal devices or ad hoc folders; instead, all documentation should be stored in a centralized and secure location so it can be retrieved consistently in the event of an audit, a repeat offense, or a similar review. Guidance that stresses that Nothing should be left in scattered files applies just as strongly to your job site documentation as it does to HR investigations.

Like Fix It Homestead’s content? Be sure to follow us.

Here’s more from us:

- I made Joanna Gaines’s Friendsgiving casserole and here is what I would keep

- Pump Shotguns That Jam the Moment You Actually Need Them

- The First 5 Things Guests Notice About Your Living Room at Christmas

- What Caliber Works Best for Groundhogs, Armadillos, and Other Digging Pests?

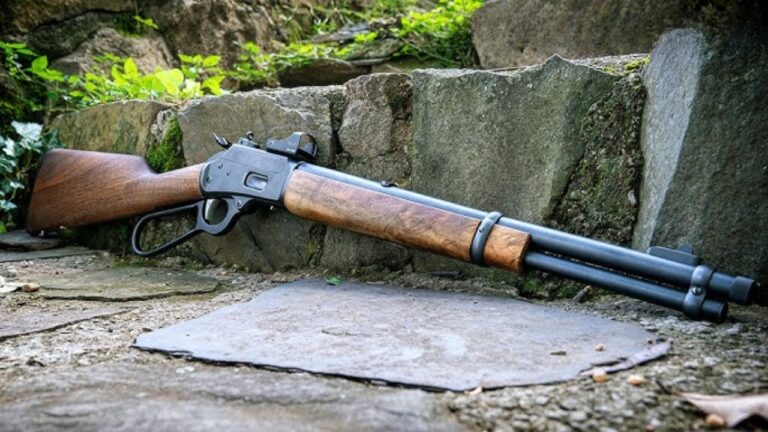

- Rifles worth keeping by the back door on any rural property

*This article was developed with AI-powered tools and has been carefully reviewed by our editors.