The mistake people make when they toss damaged parts too soon

You probably throw away more value than you realize. From a scratched cabinet door to a mis-machined bracket on the shop floor, the reflex to scrap “damaged” parts can quietly drain your budget, slow your operations, and add to a growing waste problem. The real mistake is not the damage itself, but how quickly you decide a part is beyond saving.

If you pause before tossing, you give yourself room to repair, refurbish, or repurpose components that still have life left in them. That shift in mindset, backed by disciplined processes, can protect your time, your money, and your reputation, whether you are managing a home renovation or a production line full of mission critical equipment.

Why your first instinct is to scrap, not save

Your default reaction to a damaged part is often emotional, not analytical. When a component fails in the middle of a job, it feels safer to declare it ruined and reach for a brand new replacement than to risk another failure. In industrial settings, that instinct is reinforced by the pressure to keep lines running and avoid blame, so people label parts “bad” long before anyone has diagnosed the real issue. A discussion on manufacturing work culture describes how, in a plant with many manual operations, every problem gets pinned on “the parts,” even when the root cause is process variation or operator error, which shows how easily you can confuse a fixable situation with a defective component in need of the trash bin, as one Mar thread illustrates.

That same reflex shows up in consumer life. You might assume a chipped smartphone screen, a wobbly chair, or a scratched cabinet panel is “ruined” because you are used to fast, cheap replacements. Marketing around constant upgrades trains you to see repair as second best, even when a simple fix would restore full function. When you treat every imperfection as a total loss, you skip the step of asking whether the part can be repaired, refurbished, or used as a spare, and you miss the financial and environmental upside that comes with a more deliberate decision.

The hidden cost of tossing parts too early

Scrapping damaged components before you have evaluated them properly is not just wasteful, it is expensive. In industrial environments, each year factories lose millions of dollars by assuming that new industrial parts are always the safest choice, even when a repair would restore performance at a fraction of the cost. Guidance on whether to Repair or Replace industrial components notes that repairing parts helps drive sustainability and avoid the cost and lead time of producing brand new parts, which means every premature scrap decision quietly erodes your margins.

The financial hit is not limited to the purchase price of a new component. When you discard a part that could have been refurbished, you also pay in downtime, rush shipping, and lost production. Effective spare parts strategies emphasize that having components ready to go, whether new or refurbished, keeps equipment running and reduces the need for emergency orders. When you skip repair and go straight to replacement, you often end up paying more for expedited logistics and extended outages than you would have spent on a thoughtful refurbishment plan.

Repair, maintenance, and refurbishment are not the same thing

If you want to stop throwing away value, you need to distinguish between maintenance, repair, and refurbishment instead of lumping them together as “fixing.” Maintenance is the routine work you do to keep an asset in good condition, such as lubrication, calibration, or cleaning. Repair is what you turn to when something has already failed or degraded, and you need to restore its function. Asset management experts explain that the primary objective of maintenance is to sustain operational efficiency, prevent unexpected failures, and extend an asset’s life, and that investing in maintenance reduces the likelihood of costly breakdowns while preserving structural integrity, as outlined in guidance on the Importance of Maintenance and Repair.

Refurbishment sits between those two ideas. Instead of waiting for a catastrophic failure, you proactively restore a part to a like new condition, often during a planned outage. Industrial service providers describe how Refurbishment of spare parts improves resource efficiency, supports environmental goals, and minimizes unexpected production downtime by ensuring that critical components are ready when needed. When you understand these distinctions, you can match the right strategy to each damaged part instead of defaulting to the trash can.

How a repair mindset protects your budget

Choosing to repair or refurbish instead of replace is not just a philosophical stance, it is a concrete financial strategy. When you repair a component, you typically pay for labor and a limited set of materials instead of the full cost of a new part, which can be especially significant for complex assemblies. Analysis of critical spare parts programs notes that one of the most direct financial benefits of repairing and refurbishing is the reduction in capital expenditure, since you can reuse existing components and take advantage of economies of scale in your repair processes, as highlighted in a discussion of the Effective financial benefits of refurbishing critical spare parts.

Refurbishment also helps you control downtime costs. When your mission critical equipment fails, every second it sits idle can translate into lost revenue. Energy sector case studies point out that refurbishing parts instead of waiting for new ones can Reduce downtime because you can return equipment to service faster than if you had to source and ship brand new components. Over time, a disciplined repair program lets you build a library of refurbished spares, so you are not forced into expensive last minute purchases every time something goes wrong.

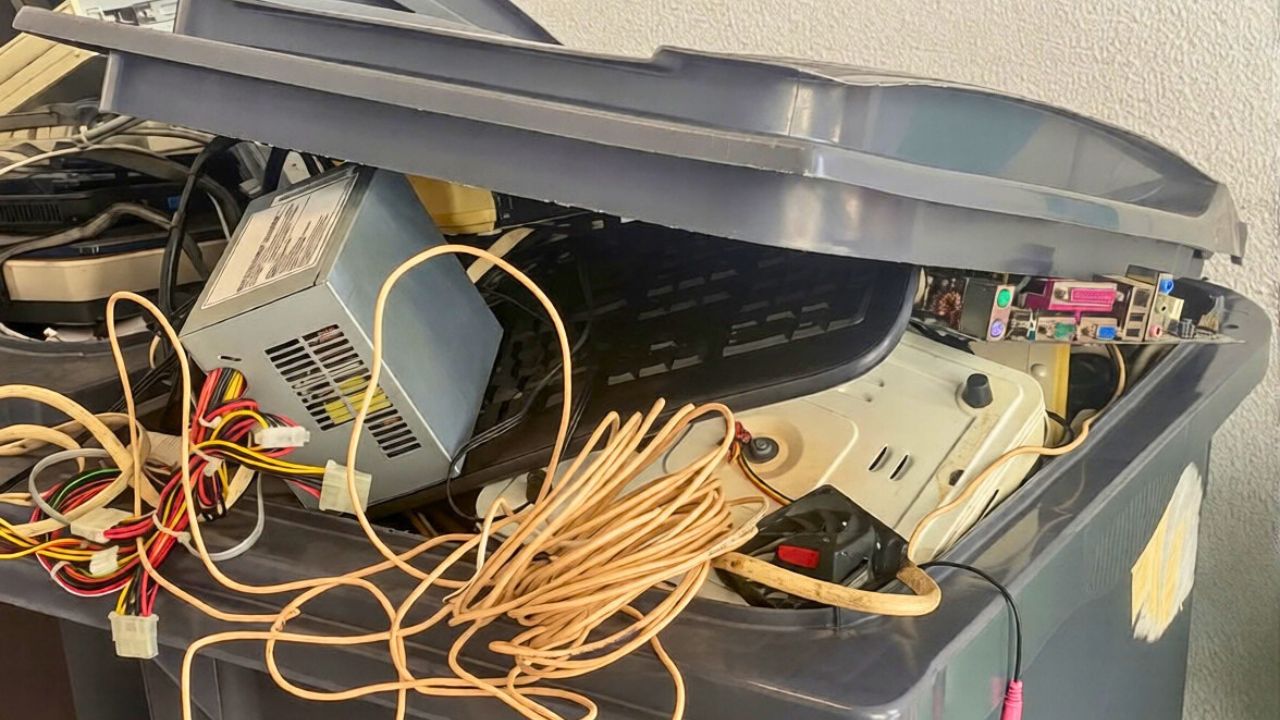

Spare parts, storage, and the value of “broken” inventory

One reason you may toss damaged parts too quickly is that you do not have a plan or a place to keep them. Without organized storage and clear labeling, a bin of “to be repaired” components turns into clutter, so it feels easier to send everything to the dumpster. Yet, when you treat damaged items as potential assets instead of junk, you can build a buffer that keeps your operations resilient. Industrial guidance on Understanding Spare Parts, Importance, Benefits, Budget control explains that having spare parts in stock reduces downtime and avoids the cost and delay of expedited shipping, enabling quicker equipment restoration when something fails.

That logic applies just as well in your garage or workshop. Advocates of more sustainable consumption point out that People often throw things away too quickly, even when broken or unused items could be stored safely and repaired later. Guidance on Sustainable Storage for and Unused Items notes that many people think replacing something is always easier, especially when new products seem like better choices, but a modest investment in shelving, bins, and labels can turn your “broken” inventory into a ready source of parts and materials for future projects.

When repair is the greener, safer choice

Every time you discard a damaged part, you are not just losing money, you are also adding to a waste stream that is already under strain. Electronics are a clear example. Thrown out devices, also known as e waste, often contain lead, mercury, barium, lithium, and cadmium, which are hazardous to human health and the environment if they end up in landfills. Waste management experts warn that Thrown out electronics should go to a specialty electronics recycling center, not the regular garbage, which means that repairing or refurbishing a device to extend its life is often the cleaner and simpler option.

Repair culture advocates argue that fixing things is one of the most accessible ways to push back against a throwaway society. They encourage you to Let fixing stuff become the norm, not the exception, and to Declare your dissatisfaction with products designed to be disposable by choosing to repair them instead. One call to action frames repair as both a practical and ethical choice, urging you to see it as a Green Thing to Do that reduces waste and conserves resources, as described in a reflection on how Let and Declare can shape a repair movement.

Warranties, insurance, and why “used” does not always mean worse

Another reason you might discard damaged parts too quickly is fear that any repair will void your protection. In reality, many manufacturers and insurers already rely on repaired or refurbished components as part of their standard practice. In the manufacturing warranty ecosystem, Component part warranty coverage plays a vital role by ensuring that individual parts, not just whole products, are backed by guarantees. This type of coverage helps manage risk, reduce replacement times, and improve customer satisfaction by recognizing that repaired or replacement components can perform reliably, as explained in guidance on Component part warranty coverage.

Auto insurance offers a similar lesson. After a collision, insurers often authorize used or refurbished parts for repairs, which can unsettle you if you equate “used” with unsafe. Legal commentary on post accident repairs notes that an Adjuster may need to review the file if you challenge the use of used parts, and that Diminished value claims can be undermined when a repair shop does poor work or uses components that need to be redone. However, the issue is usually the quality of the repair, not the fact that a part was previously used, as discussed in an analysis of how Dec decisions about parts affect claims.

Failure, blame, and the culture around damaged parts

How your organization treats mistakes has a direct impact on how quickly people scrap damaged parts. If every flawed component is seen as a personal failure, employees will be tempted to hide errors by tossing parts instead of asking whether they can be salvaged. In one discussion among machinists, a shop owner notes that Failure is always an option and that an employee would never be fired for scrapping a part unless it was done on purpose or through repeated negligence, which signals that honest mistakes are part of learning rather than grounds for punishment, as recounted in a conversation where Failure is treated as a teaching moment.

Technical investigations show how easy it is to misdiagnose the cause of damage when you rush to assign blame. Analysts studying lubricant starvation in machinery note that, Understandably, it is difficult for failure investigators and analysts to trace back the exact sequence of events that led to a breakdown, especially when cleanup and repair efforts disturb the evidence. In some cases, hasty repairs or cover ups during the cleanup can obscure what really happened, which reinforces the need for careful inspection before you label a part defective and throw it away, as described in a review of the Understandably complex dangers of lubricant starvation.

Practical guardrails so you do not void protection or create new problems

Even when you embrace repair, you still need boundaries so you do not create bigger issues by fixing the wrong thing in the wrong way. Some products come with strict warranty terms that limit what you can do yourself. For example, if your cabinet doors arrive damaged in shipping, you may void your warranty if you try to fix the damage on your own. You are often required to document the issue, follow the supplier’s return process, or accept a replacement under specific conditions, and Some companies insist on handling the repair or replacement themselves, as outlined in advice on what to do when You receive cabinet doors damaged in transit.

Safety and environmental rules also set clear lines. Certain items should never go in the regular trash, no matter how damaged they are. Electronics, batteries, and other hazardous components need specialized recycling or disposal, and Some materials are regulated because of their chemical content or fire risk. When you are deciding whether to repair, replace, or discard, you should check local regulations and manufacturer guidance, and when in doubt, route hazardous items to appropriate recycling or take back programs instead of improvising a fix that could put you or others at risk.

Like Fix It Homestead’s content? Be sure to follow us.

Here’s more from us:

- I made Joanna Gaines’s Friendsgiving casserole and here is what I would keep

- Pump Shotguns That Jam the Moment You Actually Need Them

- The First 5 Things Guests Notice About Your Living Room at Christmas

- What Caliber Works Best for Groundhogs, Armadillos, and Other Digging Pests?

- Rifles worth keeping by the back door on any rural property

*This article was developed with AI-powered tools and has been carefully reviewed by our editors.